Messy externally applied caulking and sealants on exposed-fastened metal roofs can lead to a reduced service life of the roof and attachments.

Avoid this by using only factory-applied sealants with your fasteners and brackets. Factory-applied EPDM and butyl sealants give you dependable weatherproofing without messy, unstable in-field applications.

So Where Is the Best Place on the Panel to Use EPDM vs. Butyl When Mounting Your Attachments?

It is all about "roof culture."

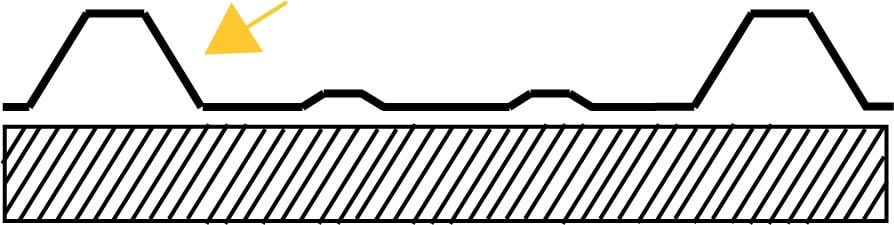

Attaching into the flat of the panel (the low valley of your corrugation or flat area between trapezoidal ribs) is commonplace in the U.S.

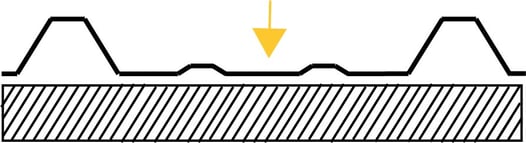

EPDM is a top choice when attaching in the high (into the rib).

For installers abroad, the penetration is in the higher point of the profile, away from the drainage plane (into the rib). These differentiators are sometimes called “bottom-fix” and “top-fix.”

When mounting in the low (valley), butyl sealant is ideal.

Need help finding the right bracket for your upcoming solar mounting project? Fill out the form to the right and we'll guide you to the right attachment.