How Do You Know What Snow Stops to Use on Your Roof? Should You Use a Snow Bar or Snow Fence System?

Learn More About the Differences Between Standing Seam and Exposed Fastener Roof Profiles.

How Do You Attach a Snow Retention System to these Roofs?

Let's start with the difference between standing seam and exposed fastener roofs.

STANDING SEAM

The profile of this roof, often abbreviated as SSR, has flat panels intersected with evenly spaced vertical legs or seams. Fastenings are concealed on these panels – hence the reason the profile is commonly called “concealed fastener”. SSRs can be attached to roof decks via clips or with a fastening flange. Fasteners are driven through clips into the roof deck but do not pierce the metal panels. The clip and the fasteners are then hidden within the standing seam. Thus, the panel is attached to the clips and locked together – either by snap-fit seam geometry or mechanically-folded during installation. SSRs come in a multitude of shapes and sizes, single-folded, double-folded, T-Shaped, Bulb-Shaped, and each are either snap-together or mechanically-seamed. The industry consensus favors standing seam, for its higher quality, ability to respond to “thermal cycling” and aesthetic design.

What is Thermal Movement?

Metal panels need to be able to expand and contract. This is called thermal movement or thermal cycling. When a metal panel heats up from the sun, it expands – increasing in length. Then it contracts when it gets cold, reverting back to its original dimensions. This thermal movement is directly related to panel length. It will also accumulate and multiply across panel sections that are joined end-to-end with mechanical fasteners. You now have two or more panels - that think they are one – all adjusting to temperature changes.

While material and finish warranties are generally the same, most standing seam systems are offered with better warranties on the entire system. Some manufacturers also offer extended assurance that the roof won’t leak (weather-tightness warranty) over some given period of time. The absence of exposed fastening and concealed clip attachment lends itself to a much lower possibility of leakage as compared to the exposed fastener system which can require hundreds or even thousands of fasteners and rubber grommets that are subject to installation error and fatigue in service because they penetrate the weathering surface, and “pin” the panel to the structure.

EXPOSED FASTENER

Exposed Fastener (commonly referred to as EF) roofs involve driving fasteners through the panels and directly into the roof deck. The edges of the panels overlap, and fasteners are screwed through both layers. The fasteners remain visible. Exposed fastener roofs are less expensive than standing seam systems. Lower cost comes from the fact that these roofs are manufactured with thinner gauge and wider-dimensioned panels, reducing material handling aspects of installation. This generally means that less roofing material is needed overall and thinner panels typically cost less. Additionally, EF roofs don’t use clips which also reduces costs (i.e. fewer components, and cheaper to install so overall total cost of roof is less).

Exposed Fastener roofs do still offer substantial protection against harsh weather elements. But it is important to note that industry standards for standing seam versus exposed fastener are not necessarily equal. So, wind uplift testing may or may not have been performed on EF roof profiles. In addition, weather-tight warranties are not included with EF roofs. Holes are required to secure roof attachment to the deck - a process that is more prone to installation error. It’s not called an exposed fastener roof for nothing.

What Snow Retention Fits My Roof Profile?

With that being said, there are three basic methods available for mounting snow retention systems to roofs. Two designs are mechanically-attached, using the process of either clamping to the seam (non-penetrating) or screwing through the roof material (penetrating); and the third method is chemically-attached and uses a “stick-on” method. This method involves gluing individual snow guards to a roof.

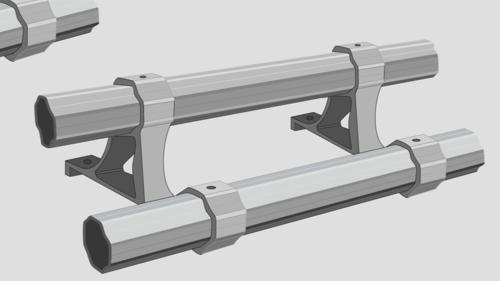

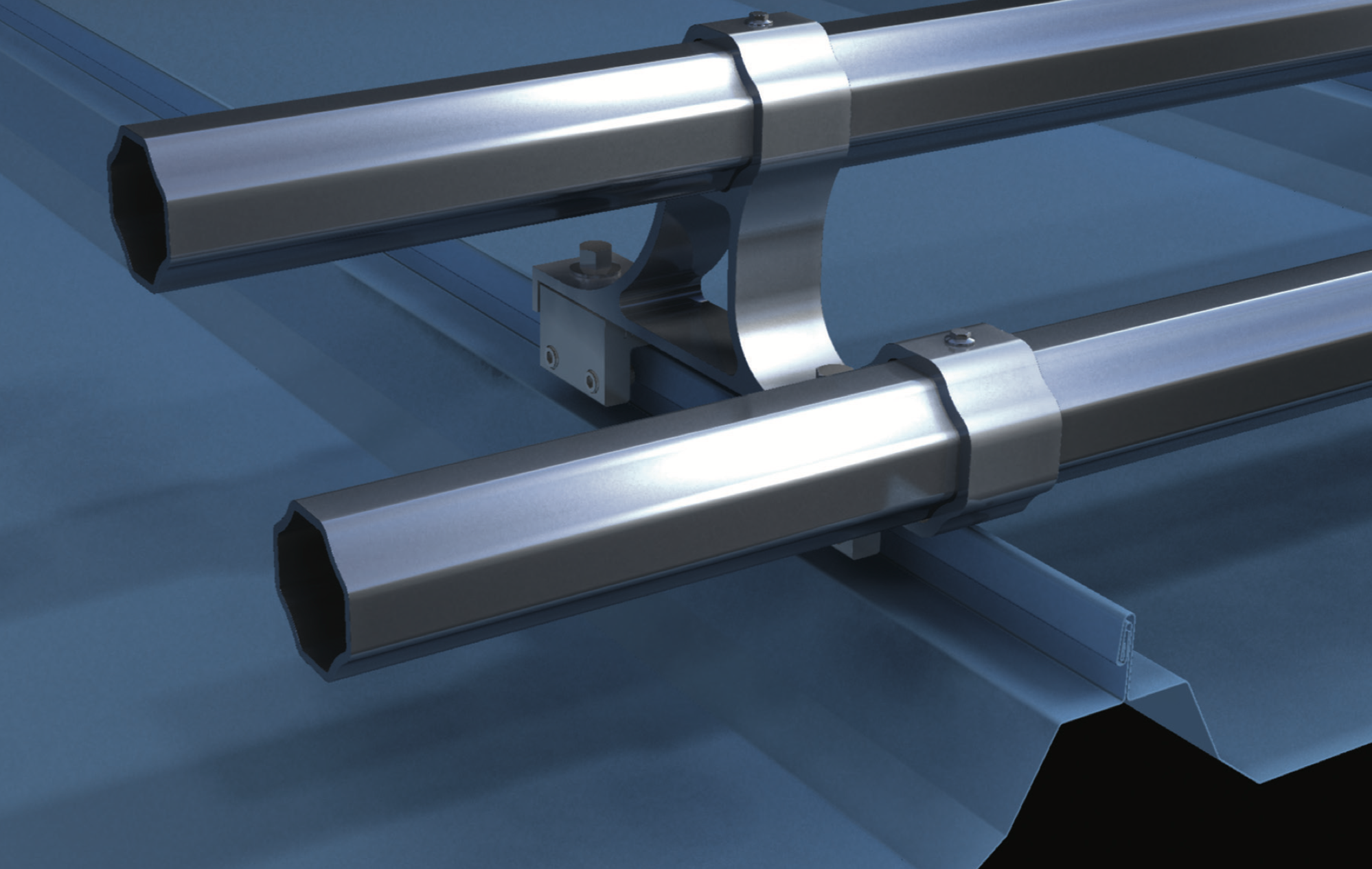

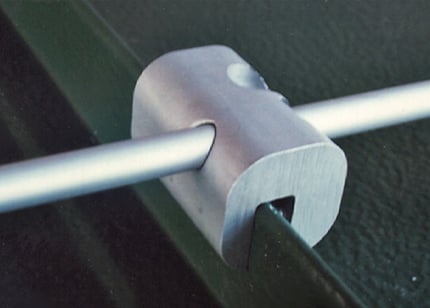

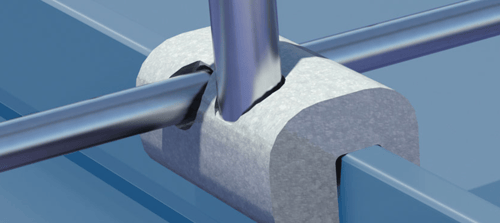

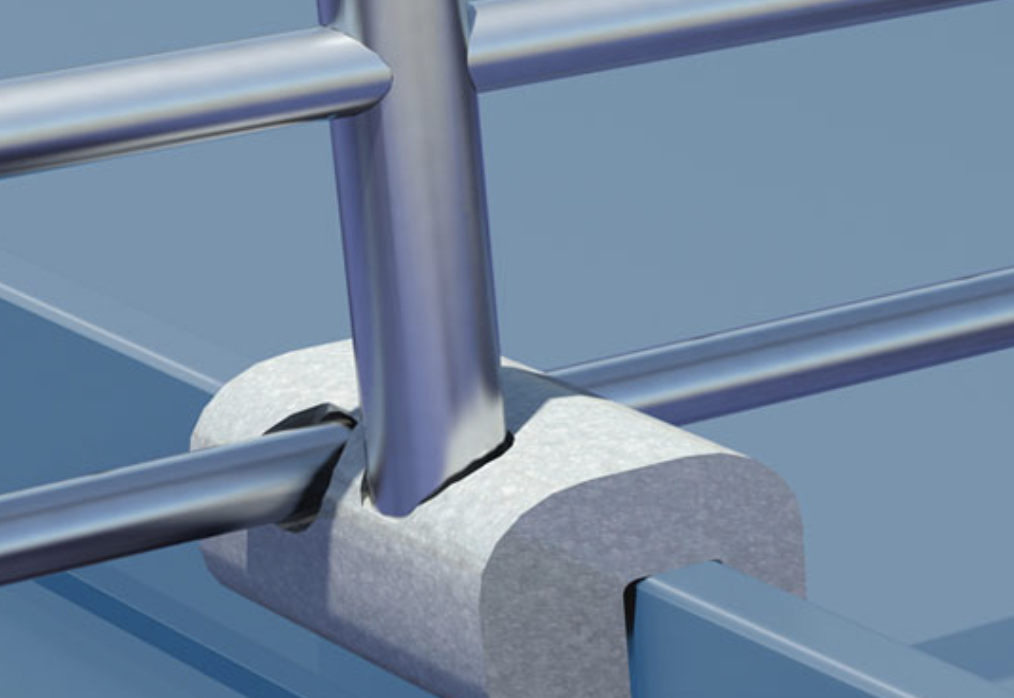

SMART SNOW STOP SYSTEMS FOR STANDING SEAM ROOFS - If you have a SSR, a clamp-to-seam snow stop is advised. Utilizing the clamp-to-seam method maintains roof warranties. The vertical legs of a standing seam roof lends itself to zero-penetration snow retention systems. That is why S-5! clamps utilize mechanical-attachment with round-point setscrews. This allows the clamps to grip the standing seam securely without penetration and without causing any damage to the panel’s protective finishes. It is important that the clamps chosen for mounting are high-quality stainless steel, and not cast or plastic. S-5! products meet all of these qualifying conditions.

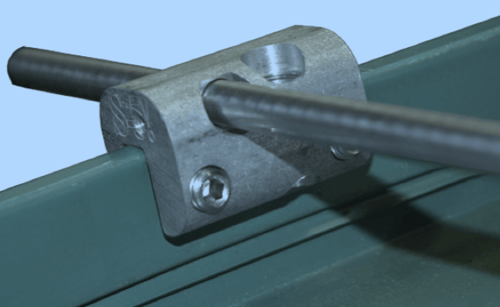

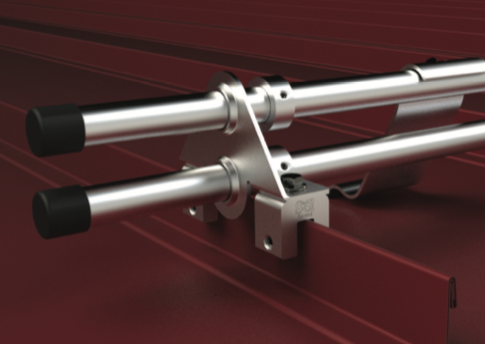

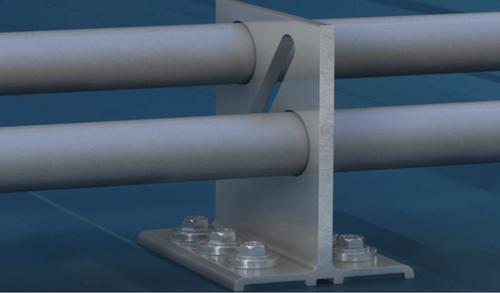

SMART SNOW STOP SYSTEMS FOR EXPOSED FASTENER ROOFS - Brackets are a secure method of attachment for trapezoidal, exposed fastener, and corrugated roof profiles. Not having a seam to clamp onto means that a different attachment method must be used. When mounting snow guard solutions to EF roofs, it is important to note the distinction between clamping and drilling a snow retention system onto a roof. Drilling requires holes. And holes in a metal roof need to be properly weather-proofed to prevent leakage. Brackets must be properly sealed to prevent UX exposure damage, drying and cracks.

LEARN MORE about why a metal roof is not just a metal roof. Standing seam and exposed fastener roofs may both be metal and may even serve similar purposes, but these two distinctly different concepts for metal roofing serve different purposes depending on location, weather, design, and more. Aesthetically-speaking and weather-wise, standing seam offers secure zero-panel-penetration as well as a long-lasting roofing solution. If cost is a big one for you, and you are also considering installing it yourself, exposed fastener may be a smart choice. Either way, S-5! has an attachment solution to serve your needs.

More Video Resources